Material & Design

Ultra Racing a Trusted Brand Worldwide

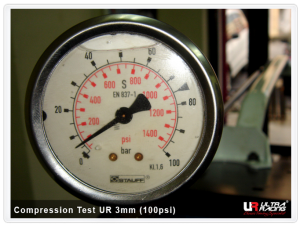

COMPRESSION TEST

Brand : UR (Civic EK 2 points)

Bracket : Non Adjustable

Bracket thickness : 4mm

Weight : 1.5 KG

Commpresion Impact : 3mm (100 psi)

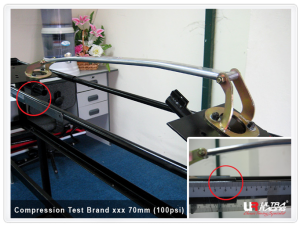

Brand : X (Civic EK 2 points)

Bracket : Adjustable

Bracket thickness : 4mm

Weight : 1.4 KG

Compression Impact : 70mm (100 psi)

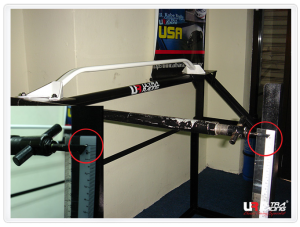

FLEX TEST

Brand : UR (Civic EK 2 points)

Bracket : Non Adjustable

Bracket thickness : 4mm

Weight : 1.5 KG

Flex : 50mm (8 kg/m)

Brand : X (Civic EK 2 points)

Bracket : Adjustable

Bracket thickness : 4mm

Weight : 1.4 KG

Flex : ? (8 kg/m)

TORSION TEST

Brand : UR (Waja 2 points)

Bracket : Non Adjustable

Bracket thickness : 4mm

Weight : 1.8 KG

Torsion : 47mm

Brand : X (Waja 2 points)

Bracket : Adjustable

Bracket thickness : 4mm

Weight : 2.0 KG

Torsion : 85mm

Brand : CCC (Waja 2 points)

Bracket : Adjustable

Bracket thickness : 3mm

Weight : 1.4 KG

Torsion : 210mm

MATERIAL SPECIFICATION & DESIGN

Every materials used are carefully selected to ensure the best performance and safety. The brackets are made of 4mm to 5mm steel plates, while the hollow steel tubes and oval tubes are of 1.2mm to 1.6mm thickness. These materials are selected to ensure the bars are rigid and strong to maintain constant geometry at all times, yet safe enough to crumble during an impact for safety reason.

All our raw materials has been made and tested with satisfactory result.

MILL / TEST CERTIFICATE (Chemical Composition)

Specification

– JIS 3101 SS 400 (Japan International Standard)

– JIS G 3141 SPCC SD (Japan International Standard)

– ASTM A 500 Grade A (American Standard)

– BS 1387 ( British Standard)

STEEL VS ALUMINUM

Why we use Steel instead of Aluminum?

First, steel is stronger than aluminum for the same size and thickness. In order for aluminum alloys to be at least the same strength as steel, it has to be at least double the thickness (steel 4mm = aluminum 8mm). When that happens, weight saving is not so apparent anymore. Of course there are also exotic materials and alloys that can match the strengths of steel, but the cost are astronomically high and therefore not very cost effective to bring into mass production.